How Much Corrosion Protection Does Zinc Plating Provide?

Zinc plating is one of the most commonly used metal finishes for protecting steel and iron components from rust and corrosion. But how much protection does it really provide, and how long does it last?

The short answer: Zinc plating provides moderate to high corrosion protection, depending on factors like coating thickness, chromate passivation, environmental exposure, and whether you're using a zinc alloy such as zinc-nickel.

At Bass Plating, we specialize in high-volume zinc and zinc-nickel plating, helping manufacturers meet performance and durability standards across industries.

How Zinc Plating Protects Metal: The Basics

Zinc plating works by applying a thin layer of zinc onto a ferrous (iron-containing) substrate such as steel. This layer provides protection in two primary ways:

1. Barrier Protection

The zinc layer acts as a physical shield, preventing moisture, oxygen, and contaminants from reaching the base metal.

2. Sacrificial Protection (Galvanic Action)

Even if the coating is scratched or damaged, the zinc corrodes in place of the steel underneath—offering continued protection against rust. This is called cathodic protection, and it's one of zinc's most valuable traits.

Factors That Influence Zinc Plating’s Corrosion Resistance

Not all zinc plating is equal. Several variables affect how much corrosion protection you can expect:

Coating Thickness

- Thicker zinc coatings provide longer-lasting protection.

- Common thicknesses range from 5 to 25 microns (0.0002” to 0.001”), depending on the application.

- At Bass Plating, we tailor thickness to meet your spec—balancing performance with cost.

Chromate Conversion Coatings (Passivation)

After plating, parts are usually dipped in a chromate solution to enhance corrosion resistance and appearance. Options include:

- Clear/Blue Trivalent – good for indoor or dry-use parts

- Yellow Dichromate – moderate to high corrosion resistance

- Black or Olive Drab – aesthetic plus functional corrosion protection

Trivalent chromates (RoHS compliant) are more environmentally friendly, while hexavalent options are still used in legacy or defense applications.

Environment

Zinc performs differently depending on exposure:

- Indoor use: Zinc plating can last 5–10+ years without significant corrosion.

- Outdoor or humid environments: Protection may last 12–24 months unless additional coatings are applied.

- Salt spray environments (e.g., coastal, automotive): Standard zinc may corrode quickly—zinc-nickel is often a better choice here.

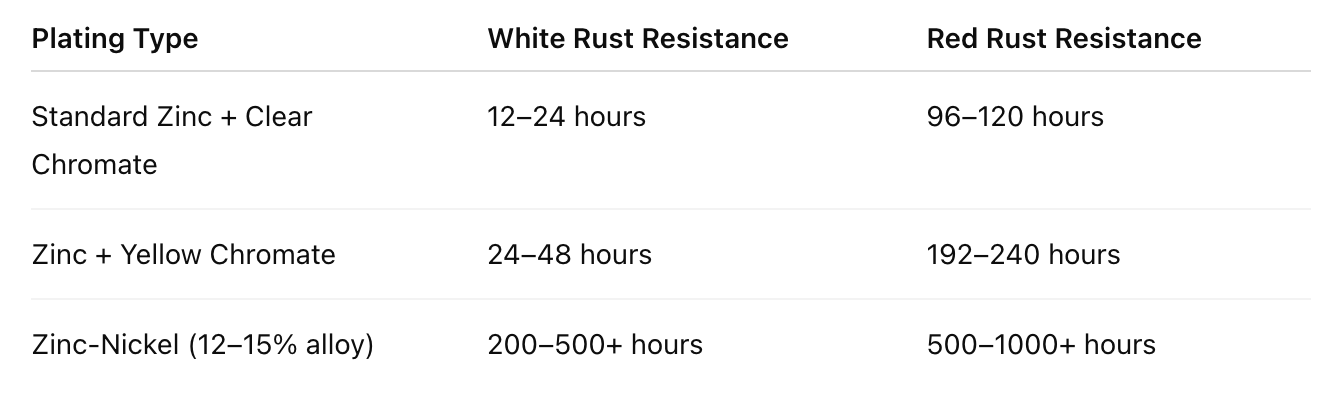

Salt Spray Testing: What Do the Hours Mean?

In the plating industry, ASTM B117 salt spray testing is used to estimate corrosion performance. Here's what you might expect:

Note: Salt spray results are lab benchmarks—they don’t always reflect real-world exposure. But they’re useful for comparing different finishes.

Zinc vs. Zinc-Nickel: When More Protection Is Needed

For parts exposed to corrosive, high-heat, or automotive environments, zinc-nickel plating is often the better option.

Why Choose Zinc-Nickel?

- Up to 10x the corrosion resistance of standard zinc

- Excellent performance in automotive underhood or marine environments

- Superior resistance to heat, oxidation, and galvanic corrosion

At Bass Plating, we offer zinc-nickel alloy plating (typically 12–15% Ni) and meet demanding OEM and military specs for long-term protection.

How to Extend the Life of Zinc-Plated Parts

To maximize corrosion protection:

- Specify the correct thickness and chromate type for your environment

- Consider a topcoat or sealer for added barrier protection

- Avoid harsh chemical exposure where possible

- For high-risk environments, upgrade to zinc-nickel plating

Need help determining what’s right for your application? Bass Plating can guide you through the options based on your industry, operating environment, and production volume.

New Title

So, how much corrosion protection does zinc plating provide? It depends on how it’s applied, how thick the coating is, what chromate is used, and where the part will be used. For many general-purpose applications, standard zinc plating offers years of protection. For more extreme conditions, zinc-nickel delivers long-term durability you can count on.

At Bass Plating, we offer:

- High-volume rack and barrel zinc plating

- Zinc-nickel plating for enhanced performance

- RoHS-compliant, environmentally safe finishes

- Fast turnaround and expert technical support

Need corrosion protection that meets your specs and your schedule? Contact Bass Plating today to get a quote or technical guidance on the right finish for your parts.